We love hearing from customers. Recently we posted a photo of parts organization day here at NE HQ, and Instagram user memorygauze asked us to write about budget-friendly ways to tackle this problem.

We laughed because, truth be told, we are also still trying to solve the mystery of parts organization. We chatted with a few of our friends (who you may recognize) to see how they organize their parts, too. Read on to learn about what we do, and how 1010 Music, Winterbloom, Omiindustriies, and Olivia Artz Modular keep their workshops tidy.

What kind of parts storage are we talking about here?

We’ll talk about both through-hole and surface-mount components here, and mostly passive components.

We have a remote team spread out across the country, but nearly all prototype modification is done at the NE HQ. That means that we do some prototyping and a whole lot of value swapping when we’re working on new things. We don’t build entire products at HQ – and this is true for 1010 Music as well – but Winterbloom and OAM do build modules, so their storage storage is a little more elaborate (and also quite pretty, not going to lie). These differences influence what we have in the way of storage.

For us, we often prototype with through-hole components. Sometimes these are on breadboards, but more often, we glue components down to actual boards and solder the circuits together like this:

Once we have a cohesive design, our contract manufacturer builds a prototype for us, which means we move to surface-mount parts. We also have a smattering of parts for repairing and building things from scratch. As a result, we have a range of values we keep on hand in various form factors, and both Stephen and Kris need access to parts so the organization scheme has to work for both of us.

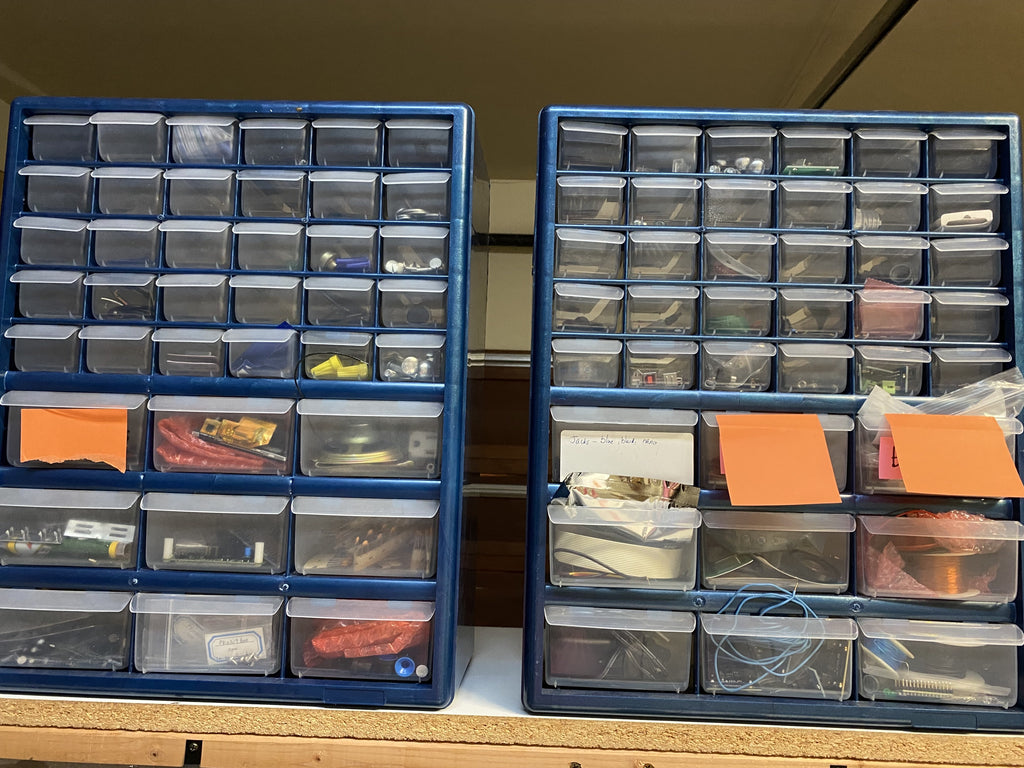

We have spent years with these things in disarray, generally inducing anxiety in our organizationally inclined friends when they visit. Our most recent incarnation of organization has been a big improvement, but I’m not convinced we have hit the nail on the head, and I kind of hate how much plastic is involved.

For tiny SMT parts, we use a BoxAll (www.aidetek.com). The boxes we have hold a few hundred compartments and they can be labeled. We don’t need to track part lot numbers on prototypes, so knowing that this bin contains 100k 0603 resistors is sufficient for our needs. We have three of these: one for each of our offices with our most commonly used parts, and a third with values we use less frequently.

For common PTH parts, we have settled on these plastic boxes that say they are for SMT parts but work well for larger things like caps and resistors. They come in a variety of sizes, and they snap together. Pair these with a label maker (yes please) and parts are organized and secure.However, the version we have (not the nice Adafruit ones) are extremely hard to get apart, and often the bins don’t open easily. While we initially bought these for SMT parts, we moved away reasonably quickly and repurposed them.

We also have a few storage organizers with drawers that hold things like knobs, light pipes, nuts, etc. On rare occasions, we build out prototypes ourselves and having a small stock of a few key things here is handy. I can’t imagine using these drawers for electronic component storage, but they are great for some uses. We’ve also found them to be just the right depth for PCBs and panels.

Finally, we have the one-off parts, or things that don’t fit in the little bins. These gave us the most trouble, by far. We’ve settled on consolidating to a metal rack with bins. These could be as simple as shoe boxes or stacking AkroBins. Again, our trusty label maker came to the rescue: we now have bins for capacitors, resistors, and more. Things in these bins stay in the bag they came in, but we’ve found over time that the Mouser labels fade, so we often Sharpie in the important details on a label.

All of this has not made my office less of a disaster.

What our module-making friends had to say

Aaron Higgins from 1010 Music sent along his lovely and compact workspace photo. He says that there are some parts he knows they will need for repairs based on past experience, so he keeps up to a 6 month supply of those on hand. For prototypes, he orders what he needs. Mouser can have parts at their office practically overnight so there's no point in trying to stock parts he might want for future prototyping. The cost and effort to store them would outweigh the convenience, in his opinion.

Liv from OAM uses a drawer strategy with color coding. She has two rainbow sets of craft drawers devoted to parts. One uses colors to sort by part type, and the other by project. Look at these happy knobs! Liv says her wife, Kate, is behind this organization: “she unleashed the power of a queer bullet-journaling academic who worked in a library for five years” on the parts-storage problem. We support anything with a rainbow color scheme, and absolutely love this system.

Stargirl Flowers wins the Biggest Overachiever Award, at least in this group. In response to my inquiry, she sent along photos of the whole Winterbloom workspace.

It looks like she’s using some of the same smaller boxes that we have used in the past as one solution. We don’t generally use enough of anything to buy reels of parts, but if you do, Stargirl has some beautiful bins that she uses to keep them neat and organized.

Similar to our drawer solution, she also has a series of craft boxes with dividers that allow storage of small parts in high volume, and some other bins for mouser bags that she has created dividers for. Everything is then neatly labeled and stored on shelves. She also has a few sets of rolling drawers with very nice inserts. Each drawer holds parts for assembling a specific project.

Since both Liv and Stargirl are building modules themselves, they each have their parts set up with a main supply but also a sub supply for building out products.

The takeaway seems to be that there’s no one-size-fits-all solution, but a variety of container sizes, a way to keep things in view, and a labeling system seem to be the common factors for everyone. We all need more excuses to break out the label maker, right?